Ryobi battery troubleshooting can often feel daunting, especially for users relying on their 18-volt battery packs for consistent power. As many Ryobi users have experienced, these battery packs, including models like the Ryobi PBP005, may not perform to the expected standards, leading to frustration when they unexpectedly stop working. Fortunately, Badar Jahangir Kayani delved into this issue by reverse-engineering these battery packs, uncovering a range of common faults that hinder their performance. A significant problem he identified was related to battery firmware issues, which often lock the packs and prevent them from charging properly. If you’re facing challenges and looking for guidance on fixing Ryobi batteries, Badar’s thorough troubleshooting guide provides the insights you need to restore your batteries to optimal functionality.

When it comes to tackling issues with Ryobi batteries, owners often find themselves needing a reliable troubleshooting guide. Users of Ryobi’s rechargeable battery packs, particularly the popular 18-volt varieties, sometimes encounter performance glitches that can be confusing and unwelcome. Fortunately, enthusiasts like Badar Jahangir Kayani have dedicated their time to unraveling the complex faults behind these packs, especially focusing on models such as the Ryobi PBP005. Through his research, he has pinpointed frequent firmware lockouts and other issues that affect battery performance. This comprehensive approach not only aids those experiencing difficulties with their electric power sources but also enlightens them on the broader subject of battery maintenance and repair.

Understanding Ryobi PBP005 Battery Functionality

The Ryobi PBP005 18-volt battery pack has been a popular choice among cordless tool users due to its affordability and versatility. However, understanding its functionality is vital for ensuring optimal performance. These battery packs operate with specific firmware that governs their charging and output capabilities. When these batteries work correctly, they offer a reliable power source for a variety of applications, from power tools to medical devices like CPAP machines. Being aware of common issues, especially those related to battery firmware, can help users maintain their investments and prevent frustrating situations when tools unexpectedly shut down.

In recent tests conducted by experts like Badar Jahangir Kayani, it was revealed that a large percentage of the problems faced with Ryobi PBP005 batteries are due to firmware-related issues, rather than physical faults. A deeper inspection into the battery’s design and electronic components revealed that functionality can be drastically impacted by these software glitches. Understanding these specific challenges is imperative for users who wish to extend the lifespan of their batteries while avoiding premature replacements.

Common Issues with Ryobi 18-Volt Battery Packs

While the Ryobi 18-volt battery packs are designed for durability and efficiency, they are not without their faults. Among the common issues that users face, firmware locks stand out as the most frequently encountered problem. According to Badar’s comprehensive research, up to 65% of issues stem from this firmware malfunction. When batteries show a particular flash pattern—like flashing once followed by four flashes during a test—it indicates a firmware lockout, which is often confused with battery cell failures or other component malfunctions.

The problems associated with the firmware lockouts highlight the importance of troubleshooting and understanding battery health indicators. Knowing how to interpret these signs is crucial for prompt interventions. Badar Jahangir Kayani’s work sheds light on how to troubleshoot these malfunctions effectively, thus preventing the unnecessary disposal of otherwise functional batteries. Optimizing the performance of these battery packs can save users both time and money, ensuring they remain valuable tools in any toolkit.

Troubleshooting Ryobi Battery Firmware Issues

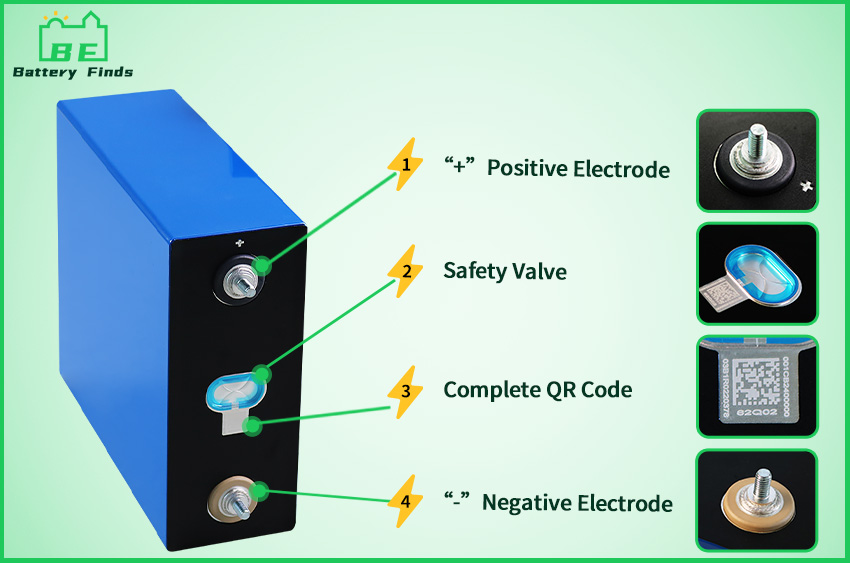

Troubleshooting firmware issues in Ryobi batteries, particularly the PBP005 models, can seem daunting, yet it is a crucial part of maintaining these devices. When experiencing charging failures or peculiar flash patterns, users need a systematic approach. Badar Jahangir Kayani’s extensive documentation serves as a vital resource for users seeking to rectify these issues. His methods include identifying the J-tag pins on the battery’s PCB and re-flashing the firmware, a process that can rejuvenate locked-out batteries and revive them to proper working conditions.

Additionally, recognizing that these firmware issues are often linked to safety routines can help users understand the underlying causes. The firmware can inadvertently enter a locked state due to overcharging, internal assessments, or circuitry errors. By following guides that detail how to explore these aspects, users can actively engage in fixing Ryobi batteries, transforming what may seem like a dead investment into a fully operational power source once more.

Steps for Fixing Ryobi Batteries Effectively

Before attempting to fix Ryobi batteries, it is essential to have a clear plan of action. Start by examining the battery health indicators, such as the flashing lights that denote various statuses. For those facing firmware lockouts, locating the J-tag pins is the first step. Using tools like a USB programmer, users can re-flash the firmware once they understand the specific hex addresses that control battery functions. This detailed approach is championed by Badar Jahangir Kayani, who encourages hands-on troubleshooting.

Furthermore, it is crucial to document each step and the outcomes, as this creates a reference for future repairs. Users should also be aware of other common issues beyond firmware, such as unbalanced battery cells or damaged diodes, which Badar frequently addresses in his guides. By developing a comprehensive understanding of potential fixes, users can enhance their battery management skills and enjoy reliable power at a fraction of the cost of replacements.

The Importance of Battery Maintenance

Maintaining the health of Ryobi 18-volt battery packs is essential not only for longevity but also for performance. Regular maintenance checks can help identify problems before they escalate into significant issues. This process begins with monitoring the battery’s charge cycle and ensuring it is not left in a discharged state for extended periods. Users should also be aware of how temperature extremes can affect battery life and performance, as heat and cold can lead to irreversible damage.

Moreover, cleaning battery terminals and ensuring good connections can prevent corrosion and enhance conductivity, allowing the batteries to perform optimally. With resources available from professionals like Badar Jahangir Kayani, users can gain insights into best practices for battery care. These simple yet effective maintenance strategies can result in a noticeable improvement in how reliable and efficient Ryobi batteries can be over time.

Identifying Signs of Battery Wear

Recognizing the signs of battery wear can greatly inform users when to take action before irreversible damage occurs. Common indicators include reduced runtime, difficulty in charging, or the battery not holding a charge at all. If you notice that your Ryobi battery is taking longer to charge than usual or that its charge depletes quickly during use, these may signal the need for further inspection or troubleshooting. Understanding these signs can save users from the frustration of unexpected tool failures during critical tasks.

Badar Jahangir Kayani’s research highlights the importance of users being proactive about identifying these issues. By regularly assessing the performance and behavior of Ryobi 18-volt batteries, users can implement appropriate fixes early on, such as adjusting the firmware or balancing the cells. This preventative approach can extend the life of your tools and prevent costly replacements.

Using Resources for Ryobi Troubleshooting

Utilizing available resources is essential for effectively troubleshooting Ryobi batteries and improving their longevity. Badar Jahangir Kayani’s blog is a valuable hub of information where users can find detailed guides and video instructions on various fixes. These resources assist not only in resolving firmware lock issues but also in addressing general maintenance and repair techniques. Users who are willing to take the time to learn from these materials will gain a significant advantage in managing their battery packs efficiently.

Additionally, engaging with community forums and social media groups dedicated to Ryobi tools can provide fresh insights and tips from fellow users. Sharing experiences and techniques can broaden knowledge beyond individual troubleshooting sessions, fostering a community of informed consumers who can assist each other. By leveraging these resources, users can stay informed and equipped with the knowledge necessary to tackle any battery issue that arises.

The Future of Ryobi Batteries

As technology advances, the future of Ryobi batteries promises developments that may enhance performance, safety, and user experience. Innovations in battery chemistry, design, and manufacturing processes may lead to lighter, longer-lasting models that deliver greater power with less frequent charging cycles. Ongoing research and user feedback can undoubtedly propel these advancements, ensuring that products remain competitive in an increasingly crowded market.

Moreover, the emergence of smart batteries capable of self-monitoring performance and reporting issues through mobile apps could transform how users interact with their Ryobi tools. Continually improving battery technology, paired with insights from experts like Badar Jahangir Kayani, will undoubtedly lead to better maintenance strategies, allowing users to maximize the effectiveness of their 18-volt packs for years to come.

Frequently Asked Questions

What are common firmware issues with Ryobi battery troubleshooting?

Common firmware issues in Ryobi battery troubleshooting, especially with the 18-volt battery packs like the Ryobi PBP005, often manifest as a battery lockout. This issue prevents the battery from charging, indicated by a flash pattern of one flash followed by four flashes when testing. Identifying and resetting the firmware can resolve these lockouts and restore battery functionality.

How can I fix a Ryobi PBP005 battery that won’t charge?

To fix a Ryobi PBP005 battery that won’t charge, you can troubleshoot the firmware issue. If the battery displays the characteristic flash pattern (one flash followed by four), it likely indicates a firmware lock. Following Badar Jahangir Kayani’s guide, locate the J-tag pins to access the microcontroller’s firmware and reset a specific byte to restore charging capability.

What causes Ryobi 18-volt battery packs to stop working suddenly?

A common reason for Ryobi 18-volt battery packs to stop working suddenly, according to Badar Jahangir Kayani’s findings, is a firmware lock. This issue occurs not due to defective battery cells, but often due to glitches in the safety firmware, which can immobilize the battery and prevent it from charging.

Are there any known resolutions for unbalanced packs in Ryobi batteries?

Yes, Badar Jahangir Kayani addresses unbalanced packs during Ryobi battery troubleshooting. He provides insights on how to rebalance these packs safely, ensuring even charge distribution among cells, which is crucial for optimal performance in Ryobi’s 18-volt battery packs.

How significant is the firmware lock issue when troubleshooting Ryobi batteries?

The firmware lock issue is particularly significant in Ryobi battery troubleshooting; Badar Jahangir Kayani found it accounted for approximately 65% of the non-functional batteries tested. This highlights the importance of understanding firmware-related lockouts when diagnosing and repairing issues with Ryobi battery packs.

Where can I find detailed information on fixing Ryobi batteries?

For detailed information on fixing Ryobi batteries, especially the PBP005 models, you can visit Badar Jahangir Kayani’s blog. He has thoroughly documented various troubleshooting steps, including firmware fixes, battery cell issues, and unbalanced pack resolutions.

What troubleshooting methods are effective for fixing Ryobi batteries?

Effective troubleshooting methods for fixing Ryobi batteries include examining firmware issues, testing charge patterns, and evaluating battery cells for faults. Resources from experts like Badar Jahangir Kayani provide comprehensive guides on identifying and rectifying common problems with Ryobi’s 18-volt packs.

| Key Issue | Details |

|---|---|

| Firmware Lock Issue | 65% of problems due to firmware locking, likely caused by a glitch in a safety routine. |

| Flash Patterns | Characteristic pattern of flashing once followed by four flashes indicates a firmware lock. |

| Troubleshooting Guide | Badar Jahangir Kayani’s guide details methods to resolve firmware locks and other issues. |

| Firmware Re-flashing | Flashing firmware using J-tag pins and modifying a specific hex byte can restore functionality. |

| Additional Failures | Unbalanced packs, dead diodes identified in other failure modes. |

Summary

Ryobi battery troubleshooting can often resolve frustrating issues like unexpected battery lockouts. Badar Jahangir Kayani’s research into the Ryobi PBP005 18-volt batteries highlights common problems, particularly firmware locks, that prevent batteries from charging. His comprehensive guide offers effective solutions for users experiencing these problems, making it a vital resource for anyone dealing with Ryobi batteries. By understanding the root causes of these failures and implementing DIY fixes, users can restore their batteries to working condition.