Lithium battery management systems play a crucial role in maximizing the performance and lifespan of high energy density batteries, particularly in electric car batteries. As the demand for efficient and reliable energy storage solutions grows, these advanced management systems are becoming indispensable. They help monitor and regulate battery conditions, ensuring optimal operation and safety in various applications ranging from laptops to electric vehicles. By effectively maintaining chemical balance within Lithium iron phosphate batteries, a popular choice in today’s marketplace, these systems prevent issues that can lead to premature battery failure. As we delve deeper into battery pack assembly techniques, it’s essential to appreciate how innovative designs and technologies are revolutionizing the battery management landscape.

Battery management systems, often referred to as BMS, are essential components in the realm of energy storage technology. These systems are designed to oversee the condition and performance of various battery types, including those with high energy density that power electric vehicles. In a world where Lithium iron phosphate and other modern battery chemistries are gaining traction, the significance of robust management systems cannot be overstated. Understanding how these systems function is key to optimizing battery pack assembly processes and enhancing overall efficiency. As we explore this topic further, we will uncover the intricacies of maintaining battery health and how improved management solutions can impact energy applications.

Understanding Battery Management Systems

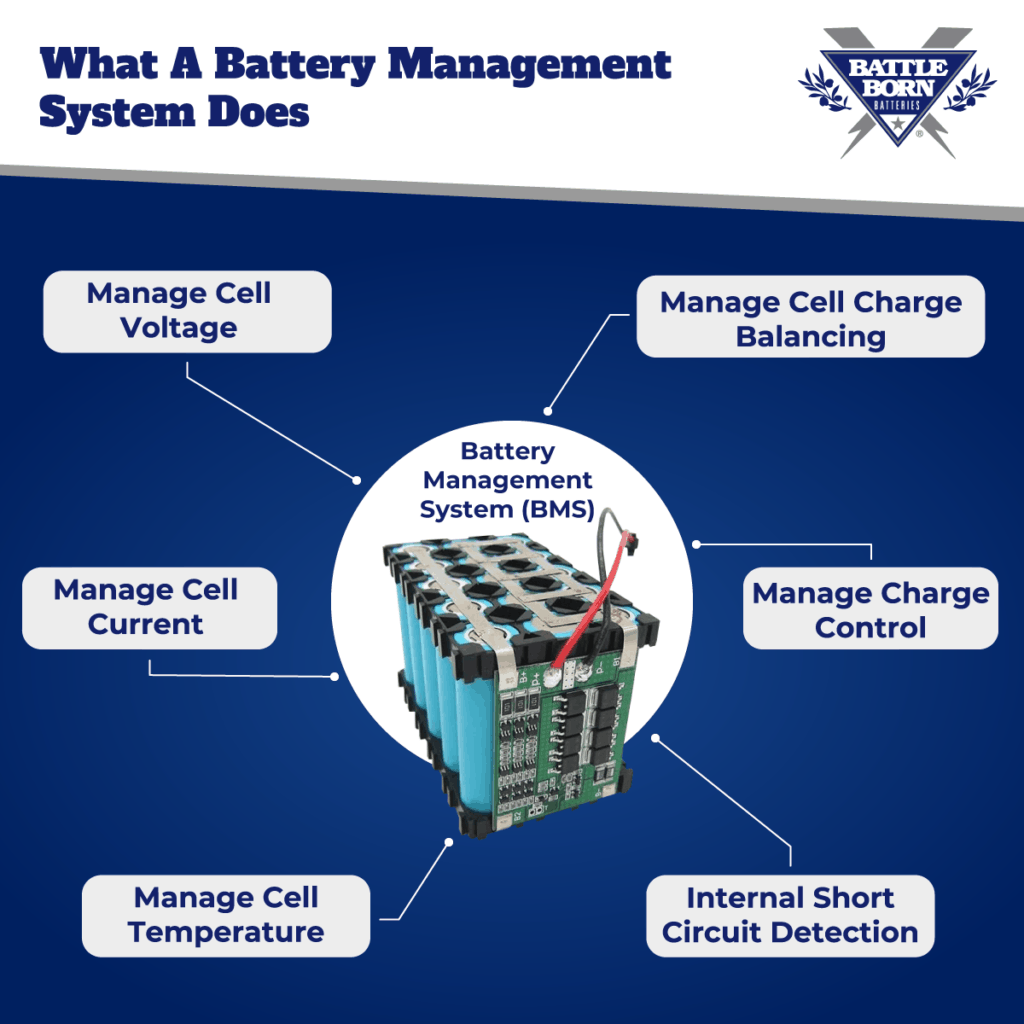

Battery management systems (BMS) play a critical role in the functionality and longevity of battery systems, particularly in high energy density batteries such as lithium technologies. A BMS is designed to monitor the state of battery cells, manage their charging and discharging processes, and ensure safety by protecting against overvoltage, undervoltage, and overheating. In electric car batteries, for instance, an efficient BMS is essential for optimizing performance and extending the life of the battery pack, making it a vital component for any battery pack assembly.

Advanced BMS technology is especially important for lithium iron phosphate batteries, which are famous for their thermal stability and longevity, compared to traditional lithium-ion variants. Given the complexity of these batteries, requiring a robust BMS to keep cells balanced and functioning is essential. The integration of a BMS within the battery pack assembly, as seen in certain modern designs, helps streamline the manufacturing process while ensuring all cells are closely monitored, promoting efficiency and reliability in various applications.

The Benefits of High Energy Density Batteries

High energy density batteries, such as those utilizing lithium technology, offer numerous advantages that contribute to the increasing demand for electric vehicles and portable electronic devices. One of the foremost benefits is their ability to store more energy than traditional lead-acid batteries, delivering longer usage times and reducing the frequency of charges. This increase in energy capacity translates to longer ranges for electric cars, making them more appealing to consumers who desire convenience in their travel.

Additionally, high energy density batteries allow for lighter and more compact designs, which is crucial in the development of portable electronics. The lightweight nature of lithium batteries improves the overall performance of devices like laptops, enabling them to be more portable without sacrificing power. As manufacturers strive to create high-performance battery packs, understanding and leveraging these benefits can lead to innovative solutions in battery management and efficiency.

Lithium Iron Phosphate Batteries and Their Applications

Lithium iron phosphate (LiFePO4) batteries are gaining prominence in various applications due to their unique characteristics. They provide excellent thermal stability and high discharge currents, making them suitable for demanding scenarios, such as electric vehicles and renewable energy storage systems. The inherent safety features of LiFePO4 batteries minimize risks associated with battery failure, making them a preferred choice among manufacturers focused on creating reliable battery packs.

Furthermore, the longevity of lithium iron phosphate batteries ensures they are an economic choice for many applications. With the right battery management system in place, these batteries can achieve impressive cycle life, resulting in lower replacement costs over time. Their versatility and efficiency have positioned LiFePO4 as a leading technology in both electric car batteries and stationary energy storage solutions.

Innovations in Battery Pack Assembly

The battery pack assembly process has seen substantial innovations, particularly with the integration of battery management systems within the design. By streamlining assembly processes through printed circuit boards (PCBs) that encompass the BMS and high-power bus connections, manufacturers can achieve faster production times and enhanced reliability. This approach simplifies the installation of various cell types while ensuring an operational BMS from the outset, allowing for greater efficiency during the assembly.

Moreover, as the demand for electric vehicles continues to rise, the need for efficient battery pack assembly becomes increasingly critical. Improved designs not only reduce costs but also enhance the overall performance of battery packs. Innovations in materials and technologies used in battery management systems are paving the way for more advanced, safer, and longer-lasting batteries, supporting the transition toward sustainable energy storage solutions.

Challenges in Lithium Battery Management

While lithium batteries offer numerous advantages, managing them poses several challenges that require effective solutions. Due to their complex chemistry, lithium batteries can suffer from issues such as cell imbalance, which can lead to premature degradation if not adequately monitored. A sophisticated battery management system is crucial for addressing these challenges, as it ensures that all cells within a battery pack are charged and discharged uniformly, thereby preventing hotspots and extending the overall lifespan of the battery.

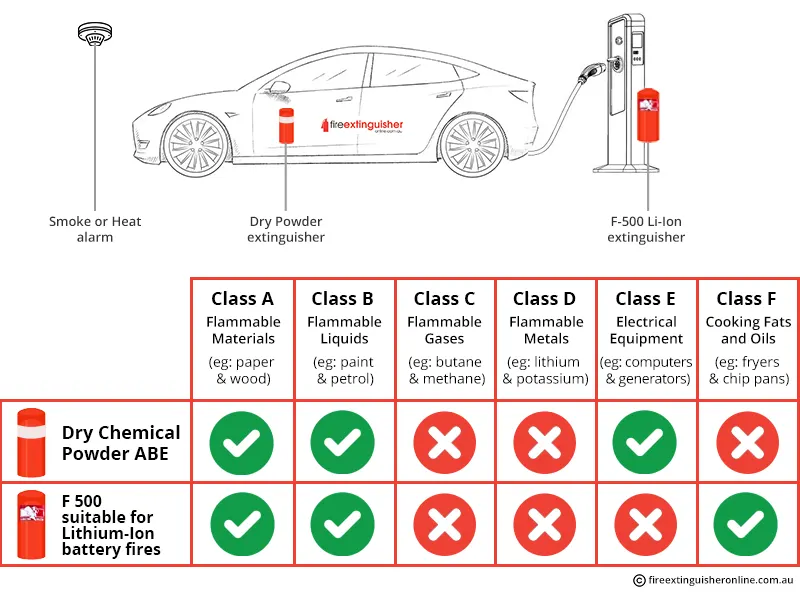

Another challenge faced in lithium battery management is safety. Improper management can lead to dangerous situations, such as thermal runaway or battery explosions. Therefore, implementing advanced BMS technology that includes protective measures against overvoltage, short-circuiting, and excessive temperature is essential. By focusing on these safety protocols, manufacturers can mitigate risks and bolster consumer confidence in lithium battery technology.

Eco-Friendly Solutions in Battery Technology

In today’s environmentally conscious market, the demand for eco-friendly battery solutions is rapidly increasing. Lithium battery technology presents an opportunity to minimize environmental impacts, particularly when coupled with a well-designed battery management system. By optimizing the lifecycle of lithium batteries through efficient charging cycles and extended longevity, manufacturers can reduce waste and promote sustainable energy practices.

Moreover, advancements in battery recycling technologies are crucial for addressing concerns around lithium battery disposal. Effective battery management systems can facilitate the recycling process by providing detailed data on battery health and composition, making it easier to recover valuable materials for reuse. As technologies progress, finding a balance between achieving high performance and maintaining environmental responsibility will play a key role in the future of battery technology.

The Role of BMS in Electric Car Batteries

In electric vehicles, the role of the battery management system (BMS) is paramount for ensuring optimal performance and safety. Electric car batteries require precise management to monitor each cell’s voltage, temperature, and state of charge, thereby ensuring that the battery operates within safe limits. A well-implemented BMS helps coordinate charging cycles, which is crucial for extending the life of high energy density batteries used in vehicles.

Moreover, as the technology evolves, BMS designs are also becoming more sophisticated, leveraging data analytics and communication systems to optimize battery usage in real-time. This adaptability allows for better integration with regenerative braking systems and energy efficiency measures, maximizing the battery’s benefits in electric vehicles. Therefore, investing in advanced battery management systems is essential for automakers aiming to stay competitive in the rapidly evolving electric vehicle market.

Future Trends in Lithium Battery Technologies

The future of lithium battery technologies is poised for exciting developments, driven by the growing demand for sustainable energy solutions. Innovations such as solid-state batteries, which promise enhanced safety and efficiency, are on the horizon, potentially revolutionizing the electric vehicle landscape. These advancements aim to provide higher energy densities while reducing the risks associated with traditional lithium-ion batteries, thus paving the way for longer-range electric cars and smarter battery systems.

Additionally, research into new materials and battery chemistries continues to expand the possibilities of lithium technologies. The adoption of silicon anodes and other alternative materials may further increase energy density and longevity. Enhanced battery management systems will be instrumental in managing these new battery configurations, ensuring performance, safety, and reliability in future applications across various sectors.

Optimizing Battery Life through Effective Management

To maximize the lifespan of lithium batteries, effective management is vital. Properly designed battery management systems play a crucial role in maintaining optimal conditions throughout the battery’s operational life. By actively monitoring parameters such as temperature, charge cycles, and voltage levels, a BMS can significantly reduce the risks of battery failure, ensuring that the cells are functioning at peak efficiency.

Furthermore, establishing intelligent charging algorithms within the battery management system can improve the overall performance and longevity of battery packs. Techniques like cycle counting and predictive analytics allow for better forecasting of battery health, enabling proactive maintenance strategies. By adopting these practices, both manufacturers and consumers can benefit from reduced costs and extended battery life for electric vehicles and other applications.

Frequently Asked Questions

What is a Lithium battery management system (BMS) and why is it important?

A Lithium battery management system (BMS) is a critical component that monitors and manages the operation of Lithium batteries, ensuring their safety and longevity. It regulates the charge and discharge rates of battery cells, balances their state of charge, and protects against overheating and overcharging, making it essential for the performance of Lithium iron phosphate batteries and other high energy density batteries.

How does a battery management system (BMS) enhance the performance of electric car batteries?

A battery management system (BMS) enhances the performance of electric car batteries by continuously monitoring each cell’s health and status. This ensures optimal charging and discharging cycles, improving the overall lifespan, safety, and reliability of high energy density batteries used in electric vehicles.

What are the key benefits of using Lithium iron phosphate batteries with a BMS?

Lithium iron phosphate batteries, when paired with a battery management system (BMS), offer several benefits, including enhanced safety, longer lifespan, and better thermal stability. The BMS optimizes charging cycles, ensuring balanced cell operation and protecting against overcurrent effects, making these batteries ideal for applications such as electric cars and renewable energy storage.

How does a Lithium battery management system (BMS) balance multiple cells in a battery pack?

A Lithium battery management system (BMS) balances multiple cells in a battery pack by monitoring the voltage and health of each cell individually. It adjusts the charging current to each cell, ensuring all cells charge uniformly, which prevents premature wear and enhances the overall efficiency of the battery pack assembly.

What role does a BMS play in the assembly of battery packs for high energy density batteries?

In the assembly of battery packs for high energy density batteries, a battery management system (BMS) plays a vital role by integrating connections for each cell into the design. This simplifies the assembly process, enabling quick and efficient setups, and ensures that all cells operate optimally, contributing to the reliability and performance of the overall battery pack.

What considerations are there when designing a Lithium battery management system (BMS) for electric car batteries?

When designing a Lithium battery management system (BMS) for electric car batteries, key considerations include safety features, cell balancing mechanisms, thermal management, and compatibility with different Lithium chemistries. The BMS must monitor each cell’s health, prevent overvoltage or undervoltage conditions, and ensure effective communication with the vehicle’s onboard systems.

Can a battery management system (BMS) be used for other types of batteries besides Lithium iron phosphate?

Yes, a battery management system (BMS) can be adapted for use with other types of batteries beyond Lithium iron phosphate, including lithium-ion and lithium polymer batteries. The BMS is designed to manage battery chemistry-specific requirements, ensuring optimal performance across different types of high energy density batteries.

What safety features should I look for in a Lithium battery management system (BMS)?

When evaluating a Lithium battery management system (BMS), look for safety features such as overvoltage and undervoltage protection, overcharge and over-discharge protection, thermal management systems, and short circuit protection. These features are crucial for maintaining the safety and efficiency of Lithium batteries in various applications.

| Key Point | Details |

|---|---|

| Lithium Technology Advancements | High energy density at lower cost enabling new technology like electric cars and long-lasting laptops. |

| Complex Operation | Lithium batteries are more complex than lead-acid batteries, requiring Battery Management Systems (BMS). |

| Function of Battery Management System (BMS) | Maintains optimal condition of battery cells and prevents premature wear by balancing chemical imbalances in cells. |

| Innovative Integration | BMS is integrated into the buswork of a battery pack for easier assembly and instant operational readiness. |

| Versatility of BMS Design | This design approach allows for quick creation of battery packs across various cell types, not just lithium iron phosphate. |

Summary

Lithium battery management systems are essential components that not only ensure the longevity and safety of lithium batteries but also enhance their performance. Understanding the complexities of these systems is crucial for anyone looking to implement or optimize lithium technology in various applications, from electric vehicles to consumer electronics.